|

Dutton

Simulation provides Computer Aided Engineering (CAE)

software for simulation of product performance and manufacturing

processes. With our support, these software

tools are used to create optimised designs at minimum

cost, saving time and money in the product design and

manufacturing cycle. Dutton

Simulation provides Computer Aided Engineering (CAE)

software for simulation of product performance and manufacturing

processes. With our support, these software

tools are used to create optimised designs at minimum

cost, saving time and money in the product design and

manufacturing cycle.

We work in partnership with our clients to allow

you to gain maximum benefit from the best value analysis

and simulation software. Our services will benefit all

involved in part design and manufacture, including designers,

process & tooling engineers and manufacturers.

Industries served include automotive, aerospace, white

goods, electronics and all forms of precision engineering.

Read

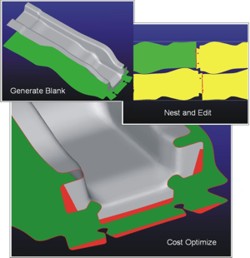

how Honda of the UK Manufacturing

have benefited from using FTI's COSTOPTIMIZER, achieving

significant savings in both material and tooling costs.

We

supply metal forming simulation software from

the world's leading developers, notably FTI Forming

Suite as well as simufact forming, joining and welding from Hexagon

(FTI) ; and DYNAFORM,

based on LS-DYNA, from Engineering

Technology Associates (ETA). We have more

than twenty years' experience in using

these systems for metal forming analysis. We

supply metal forming simulation software from

the world's leading developers, notably FTI Forming

Suite as well as simufact forming, joining and welding from Hexagon

(FTI) ; and DYNAFORM,

based on LS-DYNA, from Engineering

Technology Associates (ETA). We have more

than twenty years' experience in using

these systems for metal forming analysis.

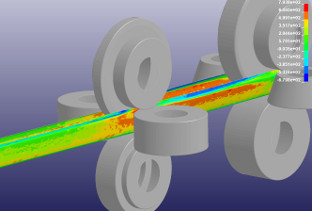

Complimenting

our sheet metal forming simulation, Dutton now provide

the roll forming design software PROFIL

from UBECO.

Section roll forming processes can be designed

and analysed using a range of techniques up to and including

FEA simulation using LS-DYNA. Complimenting

our sheet metal forming simulation, Dutton now provide

the roll forming design software PROFIL

from UBECO.

Section roll forming processes can be designed

and analysed using a range of techniques up to and including

FEA simulation using LS-DYNA.

To compliment these systems we also provide the range

of CAD translators

from Datakit

In addition to software supply and support, Dutton

Simulation provides:

If you would like to:

or have an urgent software support issue, please

send an email to

enquiries@duttonsimulation.com

and we'll get back to you as soon as we can.

|