|

Please

contact us to

arrange a trial licence Please

contact us to

arrange a trial licence

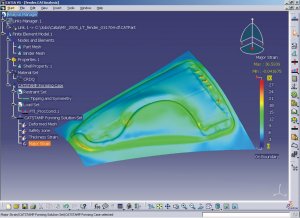

CATSTAMP

provides CATIA V5 users with detailed formability analysis

for evaluation and validation of stamped components

and draw developments. Formability analysis is based

on component or die geometry and accounts for material

properties, friction, blank holder force, pressure pad,

drawbeads, curved binder, and displacement constraints. CATSTAMP

provides CATIA V5 users with detailed formability analysis

for evaluation and validation of stamped components

and draw developments. Formability analysis is based

on component or die geometry and accounts for material

properties, friction, blank holder force, pressure pad,

drawbeads, curved binder, and displacement constraints.

• Accurately predicts feasibility of binder and

addendum geometry

• Evaluate alternate part designs and processing

conditions such as pressure pads, drawbead, and binder

layout

• Associative and regenerative draw development

analysis tool CATSTAMP integrates analysis of Draw Die

• Immediately identifies splitting, wrinkling,

and thinning

• Native integration in CATIA V5

CATSTAMP determines if a component can be stamped

consistently with minimum cost, while fulfilling all

product performance requirements. CATSTAMP is

fully integrated into Dassault Systèmes' PLM

environment.

FEATURES:

• Stamping evaluation at every stage of product

and process development

• Extensive forming conditions, such as drawbeads,

pressure pads, blank holder force and pilot holes

• Simulation results include safety zones, forming

zones, FLD, splitting, thinning, wrinkling, thickening,

stress, strain, and optimal blank shape

• Optimal blank shape stored for material costing

with nesting

• Tailor welded parts analysis with multiple weld

lines

• Customisable material database

• All results are stored in CATAnalysis file for

PLM integration eliminating multiple files

• NASTRAN and LS-DYNA thickness and strain results

for including the effects of forming in downstream CAE

applications

Download

Brochure (left mouse to open, right mouse to save to

local disk)

System Requirements:

All systems should have a minimum of 512MB RAM and

1GB free disk space.

| Platform |

Operating System |

CATIA Versionn |

Graphics |

| PC |

MS Windows 2000/XP |

CATIA V5 R14 to R17 (requires GPS module) |

System must support 1024x768 resolution with

minimum 32768 colours. |

Note: for analysis of product manufacturing

feasibility within CATIA see also CATFORM |