|

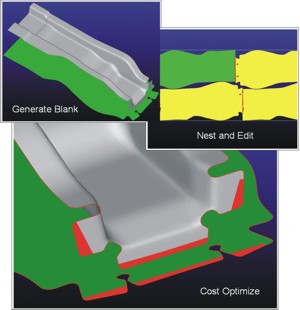

COSTOPTIMIZER

is The Material Cost Reduction Tool for Estimators,

Product and Tool Engineers. Utilising FASTBLANK

and BLANKNEST technology, COSTOPTIMIZER's unique optimization

capabilities help identify product changes that will

reduce overall material cost. These features are now

also available for CATIA V5 users as COSTOPTIMIZER

for CATIA. COSTOPTIMIZER

is The Material Cost Reduction Tool for Estimators,

Product and Tool Engineers. Utilising FASTBLANK

and BLANKNEST technology, COSTOPTIMIZER's unique optimization

capabilities help identify product changes that will

reduce overall material cost. These features are now

also available for CATIA V5 users as COSTOPTIMIZER

for CATIA.

- Identifies critical product and process design changes

to yield a 5-15% material cost reduction

- Accurately determines total material cost per blank

- Evaluates multiple nesting scenarios for optimal

material utilization

- Determines accurate blank shape for die design and

cost estimating in minutes

In addition, COSTOPTIMIZER

Advanced is also now available which

provides the blank development, nesting and material

optimisation functions with the formability and springback

analysis capabilities of FASTFORM

Advanced.

" The software is recognised

in our business as a powerful tool to reduce costs and

we will be using it as part of our product launch process

for all new programs." James

Gilmour, Johnson Controls UK. Read

more ...

Features:

• Combines blank development, nesting, and cost

optimization into one Regenerative and Associative environment

• Project-based approach enables multiple costing

scenarios that produce fully optimized nesting layouts

for cut-off dies, one-up and two-up blanking dies

• Nesting constraints include pitch, coil width,

and blank orientation to optimize layout with your equipment.

• Calculates accurate cost per blank based on supplied

input data and material utilization

• Imports surface or solid geometry from IGES,

STEP, VDA, NASTRAN and blank shapes from IGES, DXF

• Customizable materials database provides flexibility

required to simulate any material

• Blank outline can be converted into tangent continuous

lines and arcs for manufacturing

• HTML-based report generation provides valuable

engineering data for quoting and estimating

Download

Brochure (left mouse to open, right mouse to save to

local disk)

System Requirements:

All systems should have a minimum of 512MB RAM and 1GB

free disk space.

| Platform |

Operating System |

Version |

Graphics |

| PC |

MS Windows |

2000/XP |

System must support 1024x768 resolution with minimum

32768 colours |

Please contact

us to arrange a trial licence

COSTOPTIMIZER

for CATIA is the ONLY CATIA based Material

Cost Reduction Solution for Estimators, Product and

Tool Engineers. COSTOPTIMIZER

for CATIA is the ONLY CATIA based Material

Cost Reduction Solution for Estimators, Product and

Tool Engineers.

• Identifies product design changes that improve

material utilization and reduce costs

• Accurately determines total material cost per

blank

• Evaluates multiple nesting scenarios for optimal

material utilization

• The most accurate and speedy

tool for RFQ generation

COSTOPTIMIZER

identifies critical product and process design changes

to yield a material cost reduction of between 5 and

15%. COSTOPTIMIZER

identifies critical product and process design changes

to yield a material cost reduction of between 5 and

15%.

COSTOPTIMIZER for CATIA provides V5 users with a fast

and accurate method for developing blank shapes and

coil nests, and makes recommendations to alter stamped

component designs for cost reduction. It is specifically

designed for purchasers, estimators, engineers, account

managers, and tool & die designers.

FEATURES:

• Designed for fast and accurate blank generation,

nest evaluation and material cost reductions; uses the

most accurate blank development and material utilization

engines

• Produces fully optimised blanks and nesting

layouts for cut-off dies, one-up, two-up and mirrored

nesting configurations.

• Simulates multiple costing scenarios in minutes.

• Constrains pitch, coil width and blank rotation

to ensure layout is compatible with your manufacturing

equipment.

• Calculates accurate cost per blank based on

supplied input data and material.

• All results are stored in the standard CATAnalysis

file for ease of PLM integration.

Download

Brochure (left mouse to open, right mouse to save to

local disk)

System Requirements:

All systems should have a minimum of 512MB RAM and 1GB

free disk space.

| Platform |

Operating System |

CATIA Versionn |

Graphics |

| PC |

MS Windows 2000/XP |

CATIA V5 R14 to R17 (requires GPS module) |

System must support 1024x768 resolution with

minimum 32768 colours. |

Note:

- for product feasibility analysis in CATIA see CATFORM

- for blank development in CATIA see CATBLANK

- for blank nesting in CATIA see CATNEST

- for analysis of tooling feasibility within CATIA

see also CATSTAMP

|