|

Dutton Simulation offers a full service in

evaluating product design for manufacturing feasibility

in sheet metal.

Using CAD & CAE tools, we can:

-

input your product design (most major CAD systems

are supported)

-

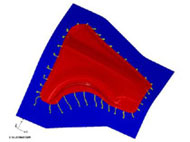

reverse trim the geometry to complete the outer

boundary (and close any internal openings), generating

the punch opening line

-

determine the die level (tip angle) for forming,

considering contact progression and depth of draw,

as well as the implications for later operations

-

create

the blankholder surface, aiming to attain a fully

developable surface where critical whilst striving

to minimise variation in draw depth create

the blankholder surface, aiming to attain a fully

developable surface where critical whilst striving

to minimise variation in draw depth

-

calculate the required addendum profiles ,

considering the need for steps and/or draw bars

for additional stretch in key areas ,

considering the need for steps and/or draw bars

for additional stretch in key areas

-

generate the draw die addendum surfaces

-

and output of the surface data as required

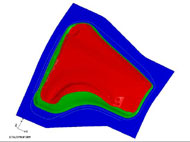

From the resulting CAD

model, we can call on the

full range of forming

simulation software to

test the tooling process

and die design.

Our approach is to use our core skills in Computer

Aided Engineering (CAE) to lead these activities, backed up with our many years'

experience in tool design and finite element analysis.

In this way we can ensure a high level of accuracy is

obtained with the quickest possible turnaround time.

to lead these activities, backed up with our many years'

experience in tool design and finite element analysis.

In this way we can ensure a high level of accuracy is

obtained with the quickest possible turnaround time.

Please contact us to

discuss your specific project requirements.

|