|

FASTFORM

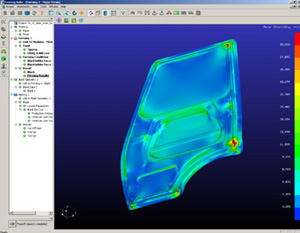

provides product and die designers with fast formability

analysis for evaluation and validation of stamped components.

Try-out simulations are based on either the component

geometry for early feasibility or on the full tool,

taking blank holder force, drawbeads, and pressure pads

into account for improved reliability. It accurately

determines if a component can be stamped consistently

with minimum cost, while fulfilling all product performance

requirements. FASTFORM

provides product and die designers with fast formability

analysis for evaluation and validation of stamped components.

Try-out simulations are based on either the component

geometry for early feasibility or on the full tool,

taking blank holder force, drawbeads, and pressure pads

into account for improved reliability. It accurately

determines if a component can be stamped consistently

with minimum cost, while fulfilling all product performance

requirements.

FASTFORM evaluates & validates

the formability of product designs & process engineering

proposals

• Predicts product and process feasibility

• Eliminates risk by identifying formability issues

up-front

• Quickly identifies splitting, wrinkling, and

thinning

• Reduces process development time by accurately

sizing blanks

• FASTFORM evaluates and validates the formability

FEATURES:

• Develops accurate blank shapes for improved material

utilization

• Introduces feasibility criteria during early

product development

• Results provide guidelines for material selection,

blank size, binder & pressure pad force, and drawbead

layout

• Simplifies results interpretation by providing

graphical display of safety zones, forming zones, splitting,

wrinkling, and thinning

• Customizable materials database provides flexibility

required to simulate any material

• HTML-based report generation summarizes the product

development process

• Fast, intuitive interface makes the software

extremely user-friendly

Download

Brochure (left mouse to open, right mouse to save to

local disk)

System Requirements:

All systems should have a minimum of 512MB RAM and 1GB

free disk space.

| Platform |

Operating System |

Version |

Graphics |

| PC |

MS Windows |

2000/XP |

System must support 1024x768 resolution with minimum

32768 colours |

N.B., For FASTFORM analysis integrated with CATIA see

CATFORM

|