|

Press tool simulation has been widely used

since the early 1990s. The goal is to take the uncertainty

out of the die design process by predicting splitting,

wrinkling, thinning, surface defects and springback

problems before any metal is cast. International

benchmarks such as those hosted every three years by

NUMISHEET

have proven the accuracy of the method (see also our

Publications for further

information). Dutton Simulation aims to bring to our

clients the benefits of using simulation as part of

the die development process by offering the best available

software, supported by a range of related services.

FASTFORM Advanced and CATSTAMP

In

addition to their superb tools for cost optimisation,

product feasibility and process engineering, FTI also

offers FASTFORM Advanced

and CATSTAMP for detailed

tooling simulation. These systems allow rapid evaluation

of tooling proposals with consideration of blankholder

curvature, blankholder pressure, drawbeads, lockbeads,

pressure pads and tooling pins. They also include advanced

features such as support for tailor-welded blanks, user-defined

blank shapes and even springback calculation. In

addition to their superb tools for cost optimisation,

product feasibility and process engineering, FTI also

offers FASTFORM Advanced

and CATSTAMP for detailed

tooling simulation. These systems allow rapid evaluation

of tooling proposals with consideration of blankholder

curvature, blankholder pressure, drawbeads, lockbeads,

pressure pads and tooling pins. They also include advanced

features such as support for tailor-welded blanks, user-defined

blank shapes and even springback calculation.

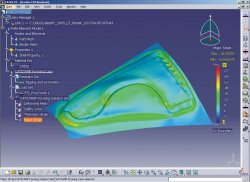

eta/DYNAFORM and Die Evaluation

Engineering

Technology Associates, Inc. (ETA) is a software development

and engineering company specializing in automotive CAE

applications worldwide. Together with LSTC, the developer

of the general purpose finite element solver LS-DYNA,

ETA has developed the DYNAFORM package

tailored for solving sheet metal forming problems.

Using DYNAFORM prior to tool build can save

significant time and cost. The latest version

offers springback compensation methods developed in

collaboration with the Big Three automotive OEMs in

North America. Engineering

Technology Associates, Inc. (ETA) is a software development

and engineering company specializing in automotive CAE

applications worldwide. Together with LSTC, the developer

of the general purpose finite element solver LS-DYNA,

ETA has developed the DYNAFORM package

tailored for solving sheet metal forming problems.

Using DYNAFORM prior to tool build can save

significant time and cost. The latest version

offers springback compensation methods developed in

collaboration with the Big Three automotive OEMs in

North America.

In addition to the core DYNAFORM system, ETA's developers

have produced a toolkit for Die Evaluation. Since

most tooling designs are done in a CAD environment,

DYNAFORM’s D-Eval Module was specially created

to support and analyze CAD based tooling and engineering

designs. Dutton Simulation also offers a range of tools

for CAD-based tooling geometry generation from our partners

at FTI and OmniCAD - please contact us for further details

The DYNAFORM package is developed from ETA's core range

of general purpose pre-

and post-processing tools for finite element

modelling and analysis (linear and non-linear) which

are also available from Dutton Simulation.

Complimenting these systems, we also supply the CAD

translators from Datakit to allow native

CAD formats such as CATIA, ProE, UG, etc to be converted

to IGES, STEP or DXF for import.

More details ...

|