|

Complete Die System Simulation

Solution

DYNAFORM is the complete die system simulation solution.

DYNAFORM allows you to entirely bypass soft tooling,

reducing overall tryout time, lower costs, increase

productivity and provide complete confidence in the

die system design. It also allows evaluation of alternative

and unconventional designs and materials for an optimal

solution. The most cost-effective and accurate

solution available, DYNAFORM is the clear choice

among progressive organizations seeking to streamline

the die analysis system.

DYNAFORM is the complete die system simulation solution.

DYNAFORM allows you to entirely bypass soft tooling,

reducing overall tryout time, lower costs, increase

productivity and provide complete confidence in the

die system design. It also allows evaluation of alternative

and unconventional designs and materials for an optimal

solution. The most cost-effective and accurate

solution available, DYNAFORM is the clear choice

among progressive organizations seeking to streamline

the die analysis system.

One Simple Interface

DYNAFORM encompasses the entire die system process in

one simple interface. By simulating every detail during

the design stage, DYNAFORM ensures the highest

quality formed part and best manufacturing process.

The system guides the engineer through cost estimation,

quoting, die face design and formability analysis. Then,

in a virtual environment, moves the part through the

stamping process inside the plant—station by station.

DYNAFORM simulates trimming/shedding and scrap removal

and analyses die structural integrity. Finally, DYNAFORM

evaluates the part transfer process within the die system

and can even simulate the behaviour of the part during

shipping.

A

Solid Infrastructure A

Solid Infrastructure

DYNAFORM offers NURBS based CAD surfaces capability.

This allows DYNAFORM’s mesh-based technology to

maintain full parametric associativity throughout the

entire simulation process. LS-DYNA, the most

powerful solver in its class, is the engine within DYNAFORM.

Offering tremendous calculation power to support difficult

modelling and simulation challenges within a die system,

these powerful processing and solving technologies enable

DYNAFORM to meet the needs of users today and those

in the future.

LS-DYNA uniquely offers both explicit & implicit

solutions that can be seamlessly switched to correctly

simulate the physics of virtually all engineering issues

of a die system including formability, springback, springback

compensation, trimming, and flanging.

The Most Accurate &

Cost-Effective Solution

The clear price/performance leader in the industry,

DYNAFORM offers pin-point accuracy in every detail and

is the key reason die designers all over the world have

turned to DYNAFORM for the most precise analysis possible.

MODULES:

BSE Blank Size Engineering

The BSE module is a complete solution for accurate blank

size estimation, nesting to maximize material utilization,

piece price and scrap calculation. BSE is based on a

one-step algorithm for rapid calculation. Potential

forming failure due to excessive blank thinning is detected

through an inverse method. BSE also creates a forming

limit diagram (FLD) map for feasibility review.

Die Evaluation

Since most tooling designs are done in a CAD environment,

DYNAFORM’s D-Eval Module was specially created

to support and analyze CAD based tooling and engineering

designs. A CAE solution, D-Eval is tailored to support

engineers in the early stages of the product design

cycle. It allows engineers to take manufacturability

into consideration early in the design process, ahead

of the tooling stage.

D-Eval Provides CAE Tools for “What If”

Studies:

- Tipping Adjustments

- Binder Generation & Modifications

- Morphing

- Drawbead Layout

- Line Bead & Geometry Bead Conversion

- Addendum Modifications

- Die Design Modifications

- CAM Trim Evaluation

- Trim Line Checks

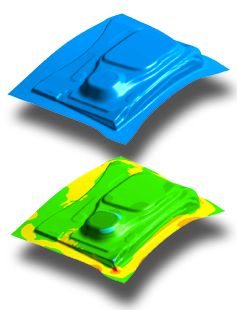

FS Formability Simulation

The FS module is a complete incremental die simulation

program for quickly generating formability results at

a very early stage of the product design cycle. It is

suited for design feasibility analysis and verification.

Stress, strain and thickening results are plotted and

a complete forming limit diagram (FLD) is generated.

It is a proven tool for uncovering hidden problem areas.

DSA Die System Analysis

DSA offers an LS-DYNA based FEA solution to analyse

die system operations including scrap shedding/removal,

die structural integrity and sheet metal transferring/handling.

Further development will include trimming, flanging

and hemming operations.

View/Download the DYNAFORM

Brochure for more details (Acrobat PDF).

Read how other companies have benefited from using

DYNAFORM (Acrobat PDF):

DYNAFORM provides full visualisation of the forming

operation as shown in the following movies

(please contact

us if you would like to see full size versions

of these and other examples):

LS-DYNA™ is a trademark of Livermore Software

Technology Corporation.

|